LM-901 machine from FRITSCH is used for the most

important process in PCB manufacturing. The LM-901 series is the basis of the

FRITSCH manual mounting systems. The machine is mainly used for :

- Ø

Picking and placing of SMD Components

- Ø

Solder paste application

- Ø

Manual Optical Support

Accuracy in placing the SMD components is maintained

due to the smooth functioning of the mounting head device.

FEATURES:

- Ø Universal circuit board holder

- Ø Component

flipping station

- Ø

Ergonomics

- Ø

Assembly head

- Ø

Dispenser

- Ø

X/Y/Z locking

- Ø

Camera

- Ø

Head Lighting

- Ø

Component dispenser

- Ø Carousel

SMD components are exceedingly small in size and are

not easy to handle by hand. Hence, this machine comes to the rescue. As the

below picture depicts, there are 3 points marked, indicating the order of

process for flipping a component. Initially, the component is placed at point

1. At point 2, an optical sensor is placed. After placement, the sensor enables

the turning mechanism and hence the component is flipped and placed at point 3.

UNIVERSAL CIRCUIT BOARD HOLDER

Adjustable screws facilitate perfect placement of PCB

Boards. In our lab, we worked by placing 3 boards at a time.

ERGONOMICS

Relocatable hand rest, facilitating component

placement with very less human error. This way, shaky hands won’t be a problem.

ASSEMBLY HEAD

The assembly head is provided with a patented

constant-force trapezoidal spring. The spring tension is distributed equally

over the entire range of the Z-axis.This assembly head consists of the main

unit that sucks up the component with a vacuum on the first click and releases

the component on the second click. If these two operations are not done, the

machine gives a “click” sort of sound.

Compressor

suction capacity: 50 l/min

DISPENSING UNIT

There is a dispenser system available to integrate

into all manipulators. Besides soldering paste and adhesive, other media can

also be dispensed. The dispenser system automatically switches on the

dispensing process as soon as the slanted dispenser needle comes into contact

with the PCB. The vertical syringe ensures that the dispenser needle does not

slip sideways when touching the PCB. Three programmable dispensing times are

available for the dispensing on different pad sizes. They can be preset in the

menu as required.

X/Y/Z LOCKING

The

X/Y-locking provides precision while placing components or dispensing paste or

glue. Individual axes can be locked. An automatic function independently locks

the X and Y axes when the component is lowered or dispensing a dot. The Z-locking enables the holding of the components in a

position of levitation close to the PCB. This simplifies the assembling of

Fine-Pitches and non-standard components because an exact calibration between

PCB and component is possible.

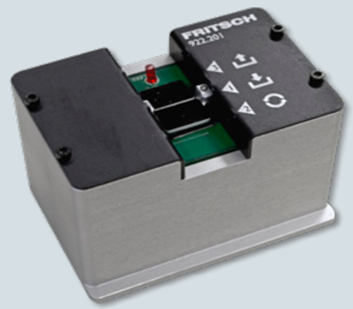

LED INDICATORS

The first LED represents the power ON/OFF. The third LED goes ON when the vacuum sucks up the component and holds tight. The second LED goes ON when the component is released.

CAMERA ,MONITOR

The camera helps in viewing the component

and the PCB board on the monitor. This way, we can check the component placement.

COMPONENT FEEDER

Light

Manipulators are equipped with the FRITSCH rail system. Various feeders can be

installed and exchanged fast – even as complete sets. This means the whole

range of SMD shapes can be processed

HEAD LIGHTING

The LEDs are

placed on both sides of the nozzle ,enabling constant and permanent lightening

under the assembling head.

CAROUSEL

Offers

smooth acceleration to transport the components gently. By using this

manual carousel ,bulk components can be supplied to the machine.

TECHNICAL DATA:

- Ø Assembly capacity is 300-600

smds/hour

- Ø Dimensions: 600 mm x 600 mm

- Ø Max. Size of PCB: 245 mm x 440 mm

- Ø Max. Assembly area: 245 mm x 350 mm

- Ø PCB thickness: 0,5 mm bis ~ 4 mm